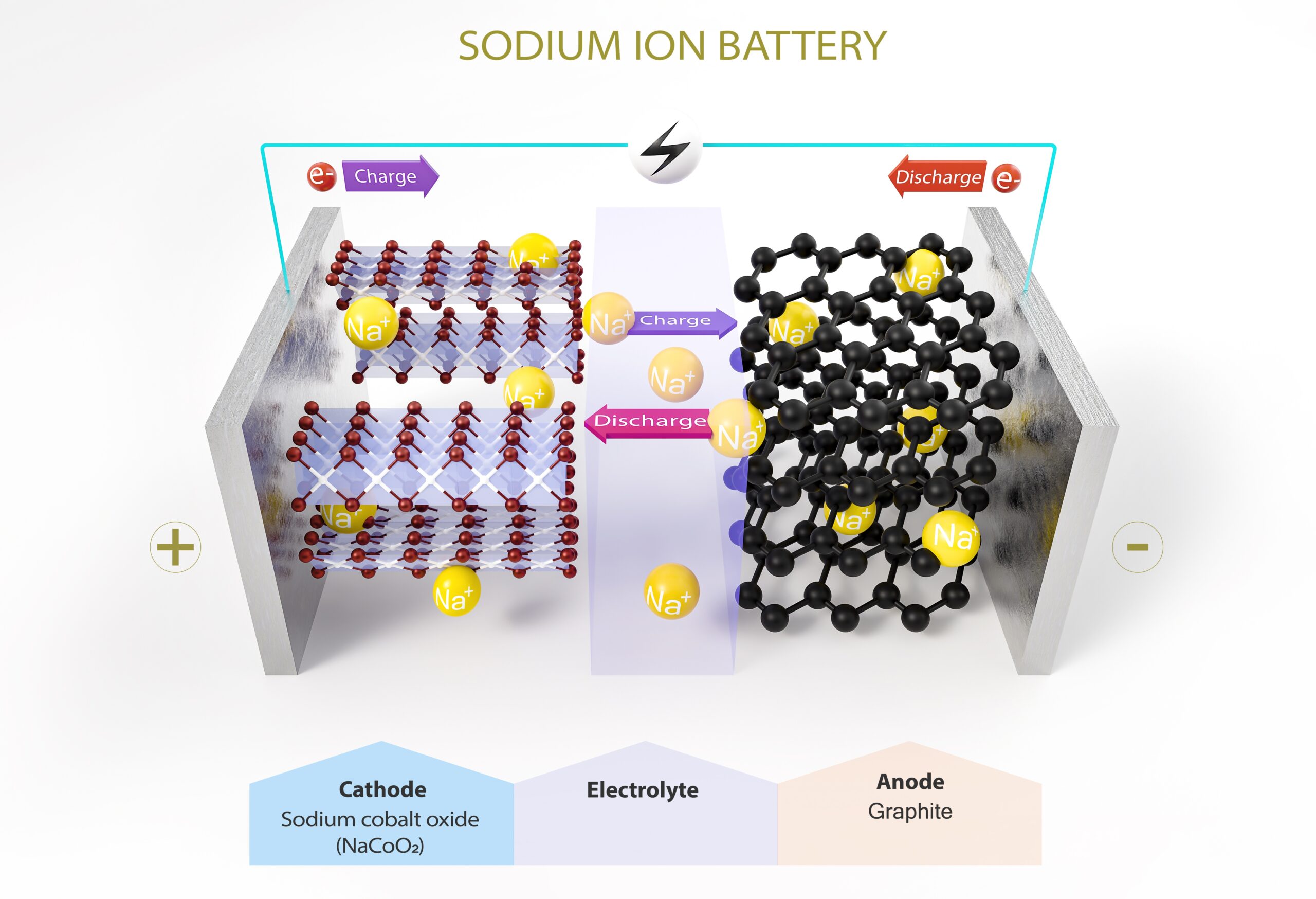

Sodium-ion batteries are gaining rapid attention as a practical and scalable alternative to lithium-ion technology. With lower material costs, abundant global resources, and promising performance improvements, this chemistry is emerging as a strong candidate for stationary storage and mobility applications. As major companies develop commercial cells and research institutes like Fraunhofer ISE refine electrode designs, sodium-ion batteries are moving from niche interest to genuine industrial momentum. Here are five things you should know about sodium-ion batteries.

1. Why Sodium Matters in Next-Generation Batteries

Sodium stands out because it is widely available and evenly distributed across global reserves. Unlike lithium, it is inexpensive to source and easier to process. These advantages make sodium-ion batteries attractive for large-scale storage where cost and sustainability matter most. Although sodium has a larger ionic radius and lower energy potential than lithium, clever electrode engineering helps reduce performance gaps. Consequently, sodium-ion technology is gaining traction in markets that seek reliable, low-cost energy solutions.

2. Specific Performance Characteristics

Sodium-ion batteries currently offer energy densities between 100 and 160 Wh/kg, depending on chemistry and design. While this is below modern lithium-ion batteries, it remains sufficient for grid storage, light mobility, and backup systems. New cathode formulations and hard-carbon anodes continue to push performance upward. Researchers also explore electrolyte blends that increase cycle life and reduce resistance. As improvements accumulate, sodium-ion cells steadily become more competitive for real-world applications.

3. Role of Hard-Carbon Anodes

Hard-carbon anodes are essential to sodium-ion success. They absorb sodium ions effectively, maintain structural stability, and operate well in wide temperature ranges. Recent studies show that optimized hard-carbon structures can retain over 80 percent capacity after long cycling periods. These gains come from tailored pore structures, modified surfaces, and refined precursor materials. Such improvements enhance both efficiency and durability, making hard-carbon a backbone material for next-generation sodium-ion batteries.

4. New Cathode Materials

Cathode chemistry strongly influences the future of sodium-ion performance. Layered oxides and Prussian-blue analogues dominate current research because they balance stability, voltage, and cost. These battery materials withstand repeated sodium insertion without major structural collapse. Moreover, optimized particle coatings improve conductivity and suppress unwanted side reactions. As a result, developers continue refining cathode blends to achieve higher capacity and better long-term stability.

5. Huge Cost Reduction

Sodium-ion manufacturing often overlaps with existing lithium-ion production lines. Many processes—coating, drying, calendaring, stacking—remain largely compatible. This compatibility reduces capital expenditure and shortens industrial ramp-up. Additionally, sodium-ion batteries avoid expensive metals like lithium and cobalt which improves cost profiles. Large producers like CATL and BYD’s FinDreams anticipate price advantages once supply chains mature. These factors make sodium-ion technology attractive to manufacturers seeking low-risk diversification.

What Comes Next?

A Fraunhofer FFB study recently demonstrated that sodium-ion batteries are on the verge of market readiness, consequently, the outlook for sodium-ion batteries is highly positive. Several companies have announced first-generation cells targeting stationary storage markets exceeding 200 GWh by 2030. Light electric vehicles, such as scooters and compact city cars, represent another promising segment. Although energy density remains lower than lithium-ion, the cost and safety benefits appeal to manufacturers. As material science advances, these batteries will likely secure a strong role in grid storage and cost-sensitive mobility applications.

How the European Battery Business Club helps to up-skill in the battery sector

You can now enroll into our Online Battery Training and broaden your knowledge in topics across the entire battery value chain. Don’t miss out on the opportunity and get to know cutting-edge knowledge with use cases from industry. The EBBC provides flexible learning programs that can enhance your career and understanding of the rapid energy transformation.

Further readings:

- Sodium-Ion Technologies, Fraunhofer ISE

- Fraunhofer FFB Study on Market Readiness of Sodium-Ion Batteries, Energy & Environmental Science Journal

FAQs on Sodium-Ion Batteries

What are sodium-ion batteries?

Sodium-ion batteries are rechargeable batteries that use sodium ions (Na⁺) instead of lithium ions (Li⁺), offering lower cost and abundant raw materials.

How do sodium-ion batteries perform compared to lithium-ion batteries?

Sodium-ion batteries currently offer 100–160 Wh/kg, which is lower than lithium-ion but sufficient for grid storage, light mobility, and backup systems.

Are sodium-ion batteries close to commercialization?

Yes, a Fraunhofer FFB study shows sodium-ion batteries are on the verge of market readiness.

What makes sodium-ion batteries cheaper to produce?

Sodium-ion batteries are cheap to produce because they avoid expensive metals like lithium and cobalt and can use much of the existing lithium-ion manufacturing infrastructure.

What materials improve sodium-ion battery performance?

Hard-carbon anodes and advanced cathode chemistries such as layered oxides and Prussian-blue analogues boost stability, capacity, and cycle life.

What applications are best suited for sodium-ion batteries?

Sodium-ion batteries are especially promising for stationary energy storage and cost-sensitive light electric vehicles.