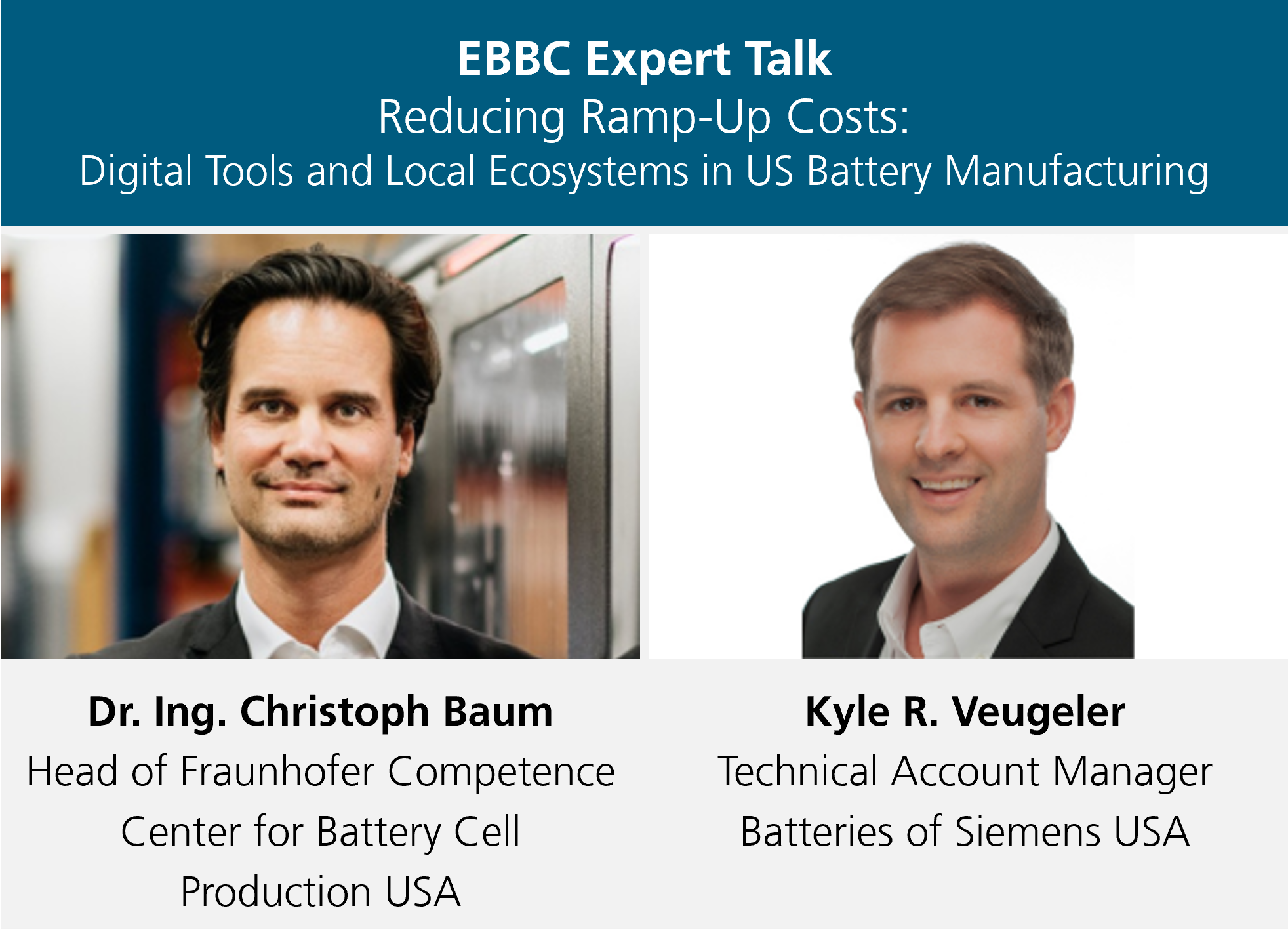

In the speedily transforming global energy market, the ramp-up phase of battery production has emerged as a critical and often precarious stage. On September 25th, 2025 the European Battery Business Club (EBBC) organized an expert talk featuring industry leaders and research protagonists. The experts discussed the challenges and opportunities in scaling battery production in the US market. Their insights highlighted the importance of addressing supply chain vulnerabilities, workforce skill gaps, the role of data strategies, and the impact of local ecosystems. This blog article captures key aspects of the discussion, providing valuable takeaways for stakeholders in the battery manufacturing industry.

Overcoming Challenges in Scaling Battery Production

Kyle R. Veugeler, Battery System Engineer and Technical Account Manager at Siemens USA opened the discussion by addressing the main challenges in ramping up battery production. “The first one would be supply chain vulnerabilities. Price volatility and trade tensions are exacerbating a lot of those commissioning ramp-ups,” he stated. To address these issues, manufacturers need to develop robust supply chain strategies that can withstand fluctuating costs and market demands. Veugeler also emphasized the pressing issue of workforce shortages, noting, “In the US alone, we have a need for around 300,000 jobs by 2030. We’re going from two facilities to about 30 facilities, I think in the next few years. So, deployments are on a faster time clock and education is not matching that time clock.” The gap in skilled labour – according to Veugeler – hinders production capabilities and limits innovation. In response to this trend, the engineers and operators must find agile ways to use the machines more efficiently and augment simulation capacities to keep pace with the rapidly growing sector.

Managing Production Costs and Scrap Rates

Dr.-Ing. Christoph Baum, Head of Fraunhofer Competence Center for Battery Cell Production USA elaborated on the financial implications of ramping up production. He remarked, “The ramp-up phase is just very cost-intensive, maybe too costly for some players to survive.” High scrap rates during initial production stages lead to significant losses, and costs can escalate if manufacturers fail to optimize their processes effectively. Baum highlighted the urgent need to transition to more reliable operation chains where scrap rates are minimized. “If you imagine the immense cost associated with creating 10, 20, or 30 percent scrap, it can cost millions a day and this is the crucial point, to get this as fast as possible to a well functional system where scrap rates go down.” he noted. When scaling from pilot production to gigawatt-scale operations, the complexity of the manufacturing equipment increases. Ensuring that operators are adequately trained and processes are clearly defined from the outset is essential for a smooth production downstream.

Technology for Efficiency

The experts stressed the transformative role of technology in scaling battery production. Baum pointed out that “battery production is a very complex process involving maybe hundreds or even more process steps which have entity dependencies. If you connect two machines, it’s pretty obvious that there is an interconnection of what the one machine makes has an influence on the other machine but you find this through the entire production chain. So, mixing parameters will have a certain influence on the interwinding parameter. (…) If you do not have a very solid database or information base for all those process parameter it is more or less impossible to make a structured root-cause-analysis in case of any failure.” Veugeler added, “Using digitalization tools, understanding why you’re using them is crucial.” He emphasized that organizations must define clear use cases for technologies like machine learning and automation. For instance, during their deployment of machine learning algorithms in 2020, Siemens USA focused on specific problems that needed solving, rather than adopting technology for technology’s sake. By leveraging these tools effectively, manufacturers can enhance decision-making and optimize production processes, ultimately leading to improved efficiency.

The Role of Local Ecosystems

The discussion also touched upon the importance of local ecosystems in supporting battery production. Veugeler explained, “The localization and those tool builders are the backbone of success for a lot of those battery factories.” Regional authorities can also have a significant influence on the success of these ecosystems by facilitating regulations and infrastructure that support local manufacturing. As Baum noted, “A stable policy environment is essential; when governments signal predictable demand for battery cells, it allows manufacturers to plan long-term investments confidently.” Furthermore, collaboration with academia is crucial, as educational institutions need to adapt their programs to meet the evolving skill requirements of the industry. Veugeler remarked, “There’s a gap in student understanding of what the industry needs versus what the industry actually needs. In university they think you have to be a brilliant electrochemist and you need to know lithium-ion diffusion coefficients when you really need someone that can understand the process of a unit operation, how to deploy that machine at scale, how do I design a redundant and resilient system. (…) The ones I talk to they’re making a shift towards more of an agile cross-trained workforce where they can have a bit of stackable credentials. You’re not an expert in one thing, you’re highly dangerous in many things.”

A Bright Future for Battery Production?

The insights shared during the EBBC expert talk underscore the complexities and opportunities in scaling battery production. As the industry faces challenges such as supply chain vulnerabilities and workforce shortages, the need for innovative solutions becomes more apparent. Looking ahead, as demand for batteries continues to rise, it appears to be essential for stakeholders to remain agile and informed. By focusing on these key areas, the battery industry can not only meet current demands but also pave the way for future advancements.

Enroll into our Online Battery Training and broaden your knowledge in Battery Manufacturing and the Battery Market. Don’t miss out on the opportunity and get to know cutting-edge knowledge with use cases from industry. The EBBC provides unique lifelong learning programs that can enhance your career and understanding of the rapid energy transformation.

FAQs on Scaling Battery Production

What measures can reduce ramp-up costs in battery production?

Measures to reduce ramp-up costs include developing robust supply chain strategies, leveraging advanced technologies for process optimization, and implementing market-oriented training programs for technicians to ensure a skilled workforce.

Why is managing scrap rates important in battery production?

Managing scrap rates is crucial as high scrap can lead to significant financial losses during the ramp-up phase.

What role does technology play in battery production efficiency?

Technology enhances efficiency by optimizing production processes and enabling better decision-making through data analysis.

How can local ecosystems support battery manufacturing?

Local ecosystems can support manufacturing by providing stable policies, regulations, and collaboration with educational institutions to meet industry skill needs.

What is the future of battery production in the US?

If current challenges such as supply chain vulnerabilities, high scrap rates, and workforce skill gaps are successfully addressed, and effective data strategies are implemented, the future of battery production in the US looks bright, with growing demand and the planning of new manufacturing facilities.