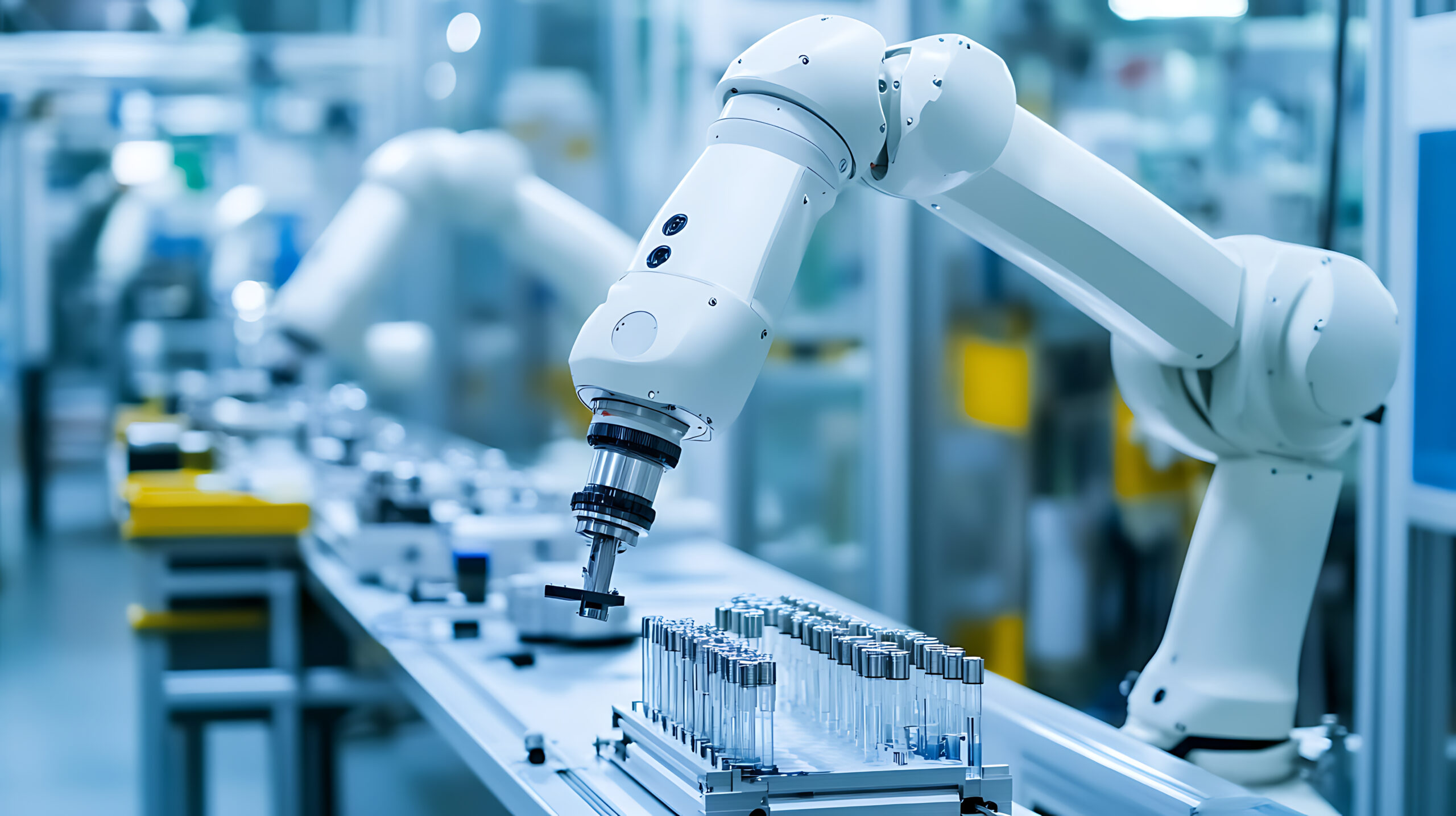

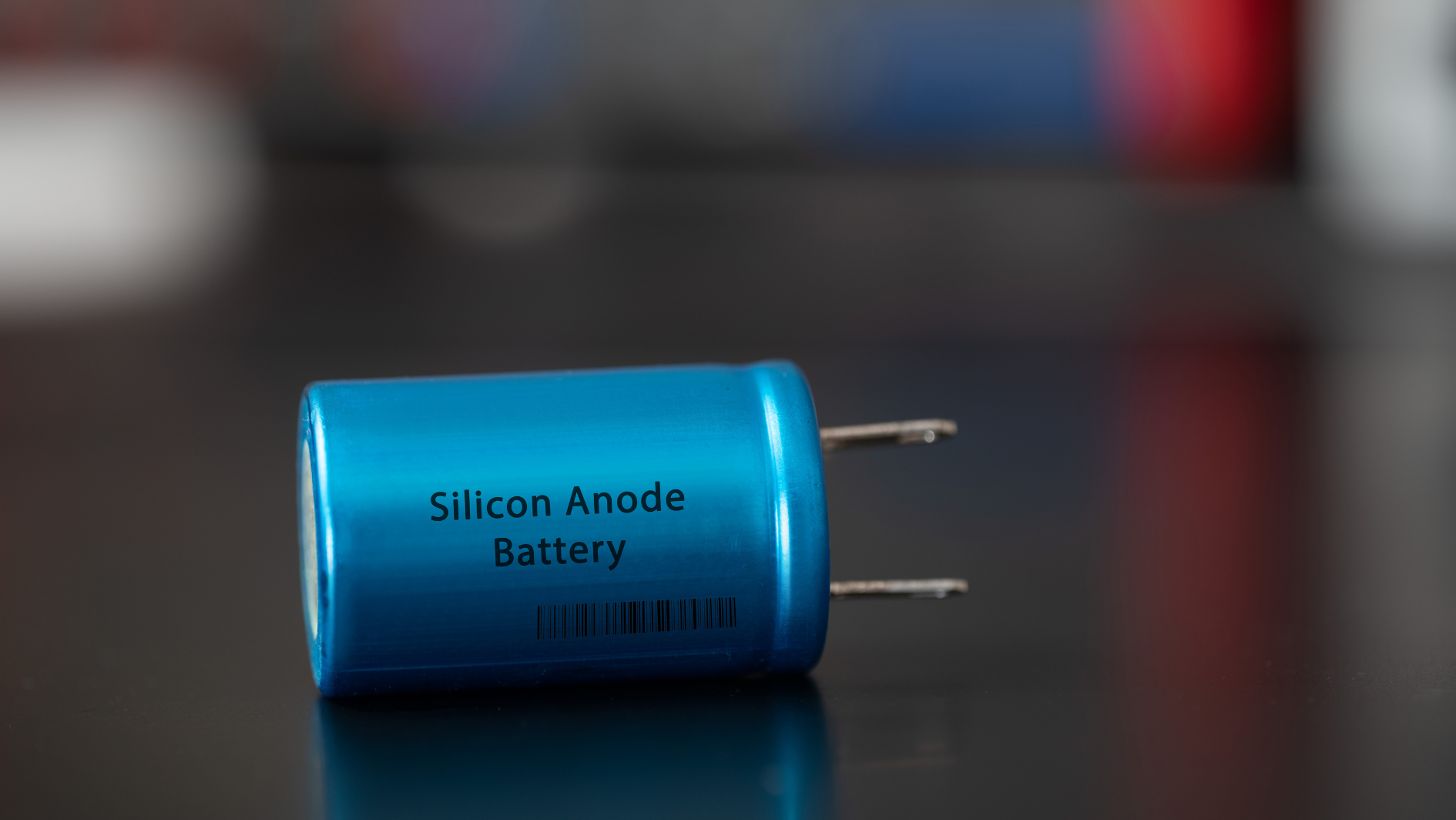

Silicon-based anodes are reshaping the potential of battery technology. Their remarkable capacity promises higher energy density, longer driving range for EVs, and more efficient storage systems. As manufacturers and researchers push to overcome volume-expansion challenges, new material blends, coatings, and hybrid designs accelerate progress. This article explores the basics behind silicon batteries and how leading research institutes advance scalable solutions for next-generation energy storage.

Why Silicon?

Silicon attracts intense interest because it stores up to ten times more lithium than graphite. This enormous theoretical capacity enables much higher energy density. Consequently, developers aim to replace part or all of the graphite in today’s anodes. Unfortunately, pure silicon expands by more than 300 percent during charging. That expansion can cause particle cracking and rapid degradation. Therefore, current battery material research focuses on silicon-carbon composites, nano-structured designs, and protective coatings that stabilize the anode while preserving high capacity.

Rising Industry Demand for High-Energy Batteries

Advancing technologies like EVs, drones and portable electronics drive strong demand for higher density cells. Silicon-based anodes can push battery energy density well beyond 300 Wh/kg and recent prototypes like the P-300N by Canadian manufacturer NEO Battery already demonstrate promising cycling stability. These gains translate into longer EV range, faster charging, or reduced pack size. As interest grows, many companies invest heavily in silicon-enhanced anode materials. Both start-ups and large suppliers see silicon as a practical way to overcome the limitations of conventional lithium-ion batteries.

Overcoming the Volume Expansion Challenge

Volume expansion remains the biggest issue for silicon. When silicon absorbs lithium, it swells dramatically. This expansion stresses the electrode, breaks electrical connections, and destabilizes the solid–electrolyte interphase (SEI). To counter these issues, researchers use nano-structuring, flexible binders, and engineered surface layers. Each approach aims to maintain structural integrity through many charge cycles. Although these strategies add manufacturing complexity, they can significantly improve durability.

Silicon–Carbon Composite Designs

Silicon–carbon composites currently offer the best balance of performance and durability. Carbon matrices provide mechanical support, reduce expansion stress, and improve conductivity. Furthermore, carbon frameworks help stabilize the SEI. The German reasearch institute Fraunhofer ISE investigates silicon-enhanced anodes within advanced pilot-scale environments. Their team focuses on controlling particle morphology and improving binder systems that withstand repeated expansion. Fraunhofer ISE also examines how silicon interacts with next-generation electrolytes in high-voltage cells.

Nanostructures and Coatings

Nanostructuring is a key strategy for improving silicon performance. Smaller particles experience less internal stress and maintain better electrical contact. Coatings made from oxides, nitrides, or polymers further protect the silicon surface and control SEI formation. A recent study published by Electrochimica Acta shows coated nano silicon retaining over 80 percent capacity after several hundred cycles. These enhancements reduce degradation and create a stable interface between the anode and electrolyte. As coating technologies improve, their industrial relevance grows significantly.

Market Outlook

Analysts expect hybrid silicon–graphite cells to reach broad commercial adoption over the next few years. Full-silicon anodes will follow once expansion and durability challenges are fully mastered as blending silicon with graphite requires precise mixing, coating, and drying routines. Suppliers like Porsche-backed Group14 Technologies expand facilities to meet rising demand for silicon powder, nano-silicon, and composites. The US battery start up GDI expects its anodes to be in EV battery cells and on the road by 2030. These developments indicate strong industrial confidence in silicon technology.

You want to get to know more on silicon-anodes? Start learning now!

Enroll into our Online Battery Training and up-skill in battery material application. The EBBC provides unique lifelong learning programs that can enhance your career and understanding of the rapid energy transformation.

Further readings:

- P-300N: Advanced Silicon Battery Achieved Over 90% Capacity Retention at 300 Cycles, NEO Battery Materials

FAQs on Silicon-Based Anodes

What are silicon-based anodes?

Silicon-based anodes are battery components that utilize silicon to store lithium, offering up to ten times more capacity than traditional graphite anodes.

Why are silicon-anodes important for EVs?

Increased energy density of silicon-anode batteries is crucial for EVs as it enables longer driving ranges and faster charging times.

What challenges do silicon-based anodes face in battery technology?

The primary challenge of silicon-anode batteries is volume expansion because silicon can expand by over 300% during charging, leading to particle cracking and rapid degradation.

How do silicon-carbon composites improve battery performance?

Silicon-carbon composites offer a balance of performance and durability. The carbon matrix provides mechanical support, reduces expansion stress, and stabilizes the solid electrolyte interface (SEI).

What role do nanostructures play in silicon anode technology?

Nanostructures help reduce internal stress and improve electrical contact in silicon anodes. Coatings made from materials like oxides and nitrides protect the silicon surface, enhancing cycling stability and reducing degradation.

What is the market outlook for silicon-based battery technology?

Hybrid silicon-graphite cells will gain commercial adoption until 2030, with full-silicon anodes expected to follow as durability challenges are addressed.